Gear Motor Principles: Boosting Speed and Energy Efficiency in Medical Equipment Production Lines

The medical equipment industry is undergoing a period of rapid innovation, driven by advancements in diagnostics, treatment, and patient care. This evolution demands precision, reliability, and increasingly, energy efficiency. At the heart of many critical medical devices – from surgical robots and imaging systems to infusion pumps and lab automation – lies the gear motor. Understanding the principles behind these vital components is crucial for optimizing production lines, reducing operational costs, and ultimately, improving patient outcomes. In today’s landscape, with increasing focus on sustainability and the rise of Industry 4.0, the role of gear motors is becoming even more significant.

What is a Gear Motor and Why is it Important?

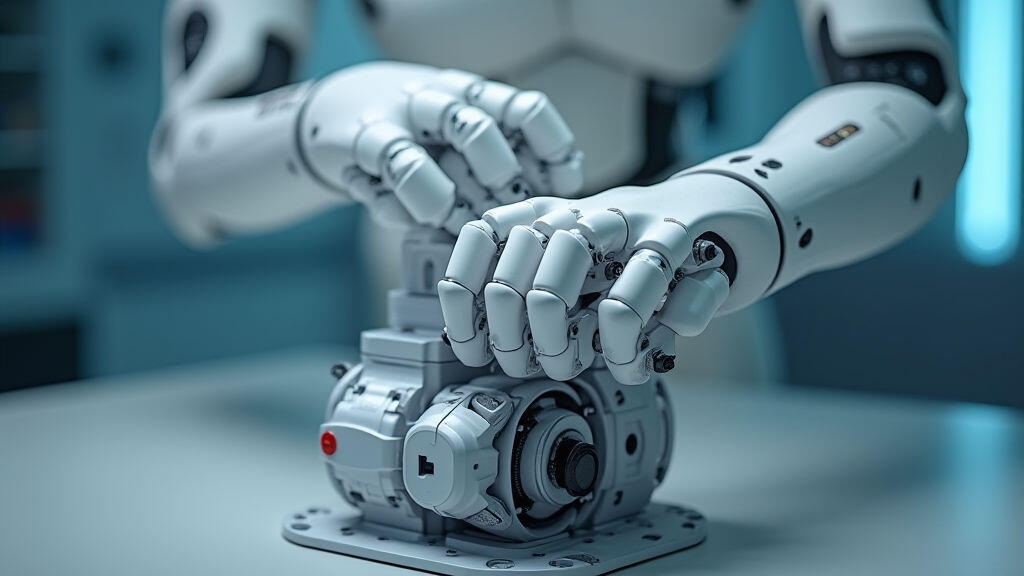

A gear motor is essentially an electric motor coupled with a gearbox. The motor provides the rotational power, while the gearbox modifies the output speed and torque. This combination offers a multitude of advantages vital for medical equipment:

- Torque Multiplication: Electric motors often produce relatively low torque. Gearboxes significantly increase torque, allowing the motor to power heavy components like robotic arms or pumps with greater ease.

- Speed Reduction: Many medical applications require controlled, low-speed movements. Gearboxes reduce the motor's speed to meet these specific needs. This is critical for delicate surgical instruments and precise positioning systems.

- Precise Control: Gear motors, especially those incorporating sophisticated control systems, enable exceptionally accurate and repeatable movements. This is paramount for applications like drug delivery and imaging.

- Compact Design: Compared to alternative solutions, gear motors offer a compact and lightweight solution for generating the necessary power and motion.

Types of Gear Motors Utilized in Medical Equipment

Several types of gear motors are commonly employed in medical equipment, each with its own strengths and weaknesses:

- Spur Gear Motors: Simple and cost-effective, spur gear motors offer high efficiency for moderate speed and torque requirements. They are widely used in applications like infusion pumps and diagnostic equipment. However, they tend to be noisier than other types.

- Helical Gear Motors: These provide smoother and quieter operation than spur gears, making them suitable for applications where noise is a concern, such as patient monitoring systems. They are also capable of handling higher loads.

- Planetary Gear Motors: Offering high torque density and compact size, planetary gear motors are ideal for space-constrained medical devices, like miniaturized surgical tools. They provide excellent performance and are becoming increasingly popular.

- Worm Gear Motors: Known for their high reduction ratios and self-locking capabilities, worm gear motors are employed in applications requiring precise holding torque, such as surgical positioning systems that need to maintain a stable position even when power is removed.

The Role of Energy Efficiency – A Critical Imperative

With growing concerns about environmental sustainability and healthcare costs, energy efficiency is no longer a “nice-to-have” but a fundamental requirement in the medical equipment industry. High energy consumption translates to increased operational expenses and a larger carbon footprint.

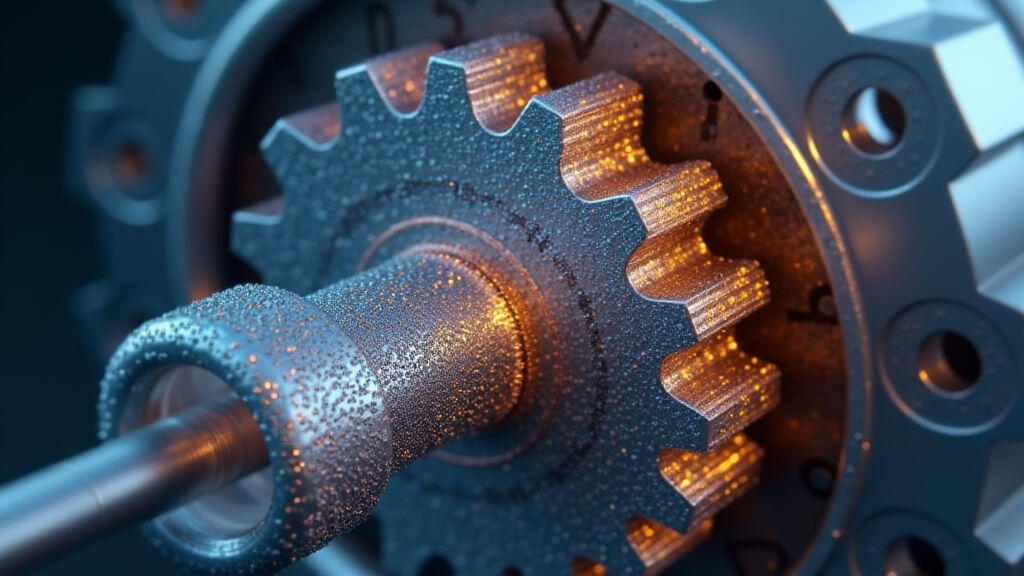

Gear motor technology has evolved significantly to address this challenge. Several innovations are contributing to improved energy efficiency:

- Advanced Materials: Using lighter, stronger materials in gearbox components reduces friction and energy losses.

- Optimized Gear Designs: Advanced CAD/CAM techniques are utilized to design gears with improved tooth profiles and reduced backlash, minimizing energy dissipation.

- High-Efficiency Motors: Pairing the gearbox with high-efficiency electric motors, such as permanent magnet synchronous motors (PMSM), further enhances overall energy performance. PMSM motors offer significantly higher efficiency compared to traditional induction motors.

- Smart Control Systems: Implementing sophisticated control algorithms like closed-loop feedback control and regenerative braking can optimize motor performance and reduce energy waste. For example, adjusting motor speed based on the actual load demands, rather than running at a constant speed, can save significant energy.

MES-Drive: Leading the Way in Energy-Efficient Gear Motor Solutions

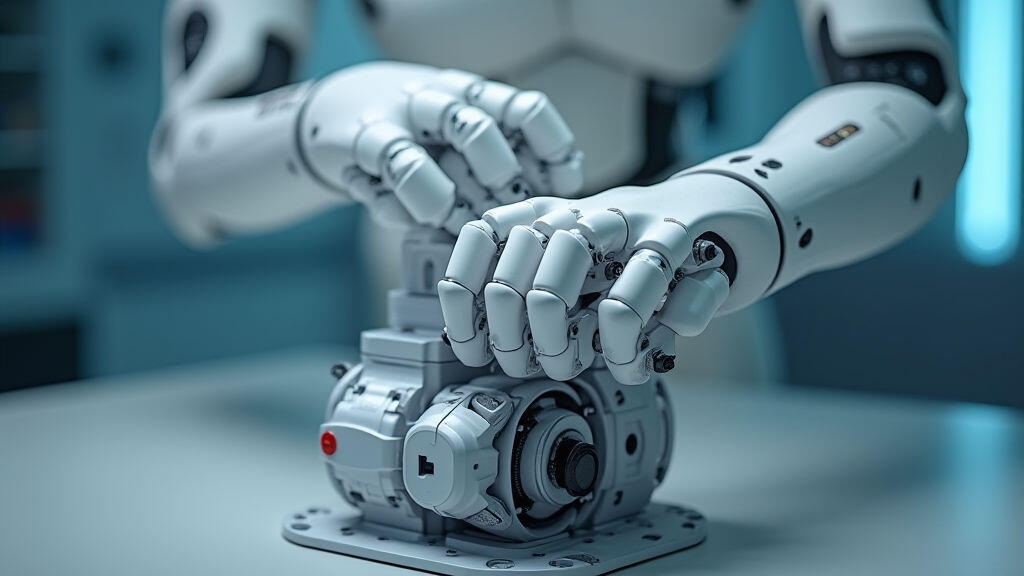

MES-Drive is a leading manufacturer of high-performance gear motors specifically tailored for medical equipment production lines. We understand the critical need for precision, reliability, and energy efficiency in this demanding industry. Our range of gear motors incorporates the latest advancements in materials science, gear design, and motor technology.

MES-Drive’s solutions boast:

- Up to 95% Energy Efficiency: Our PMSM-driven gear motors achieve exceptional energy savings.

- Reduced Noise Levels: Helical and planetary gear options minimize noise pollution in patient environments.

- Customizable Solutions: We offer tailored gear motor designs to meet the specific requirements of individual medical devices.

- Robust Reliability: Rigorous testing and quality control ensure long-term reliability and minimal downtime.

The integration of intelligent monitoring systems allows real-time energy consumption tracking and predictive maintenance, further optimizing operational efficiency. We are actively researching and implementing energy harvesting technologies within our gear motor systems to recapture energy during braking and return it to the power grid, or directly to the device for auxiliary functions.

Industry 4.0 and the Future of Gear Motors in Healthcare

The advent of Industry 4.0, characterized by interconnected devices, data analytics, and automation, is revolutionizing the medical equipment industry. Gear motors are at the epicenter of this transformation.

- Predictive Maintenance: Sensors embedded within gear motors can monitor vibration, temperature, and other parameters to predict potential failures, enabling proactive maintenance and minimizing downtime.

- Remote Monitoring and Control: Connectivity allows for remote monitoring of gear motor performance and adjustments to operating parameters, facilitating efficient troubleshooting and optimization.

- AI-Powered Optimization: Artificial intelligence can analyze data from connected gear motors to optimize performance, predict energy consumption, and identify potential inefficiencies. This leads to significant cost savings and improved reliability.

- Additive Manufacturing (3D Printing): 3D printing is enabling the rapid prototyping and custom manufacturing of gear motor components, leading to faster development cycles and the creation of highly specialized designs.

Conclusion: Powering Progress with Efficiency

Gear motors are indispensable components in modern medical equipment, directly impacting performance, reliability, and energy consumption. The industry’s relentless pursuit of innovation, coupled with the increasing focus on sustainability and the rise of Industry 4.0, is driving significant advancements in gear motor technology. MES-Drive is committed to delivering cutting-edge gear motor solutions that empower medical equipment manufacturers to achieve greater precision, reduce operational costs, and improve patient outcomes. As healthcare continues to evolve, and with the rising urgency to meet carbon reduction targets, the importance of highly efficient and smart gear motor technology will only continue to grow. The applications extend from sophisticated surgical robots to small, battery-powered diagnostic devices, making gear motors the unsung heroes of progress in healthcare.

Leave A Reply

Your email address will not be published. Required fiels are marked